Gurit® – Core materials

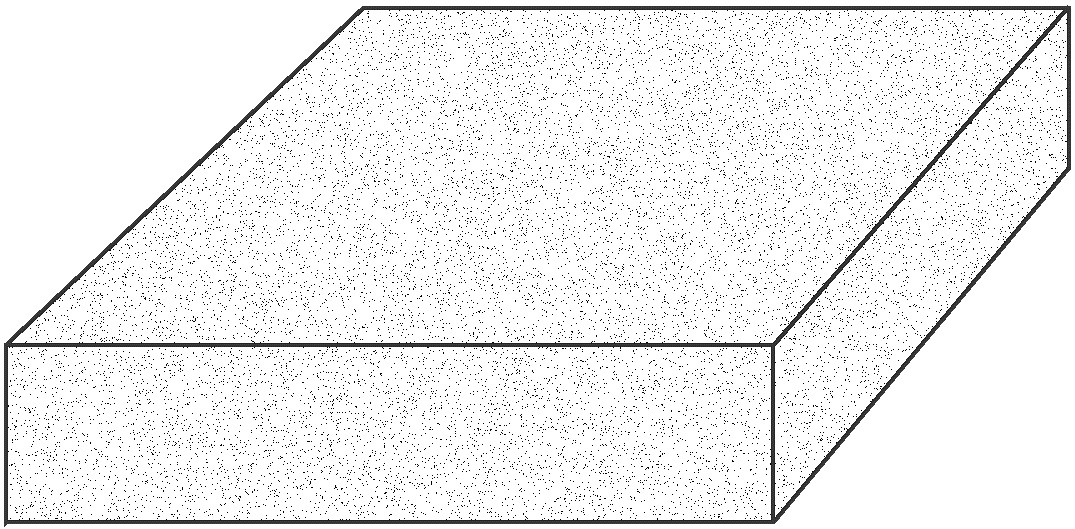

Gurit is a leading company in core material development and manufacturing. Core materials in a sandwich structure make the composite stiffer and lightweight. Gurit’s versatile product range includes suitable core material regardless of the specifications and manufacturing processes. Core materials are available in plain or contour scrim.

Ideal storage temperature is 10 – 30 ºC and relative humidity under 70 %. Should not be exposed to direct sunlight.

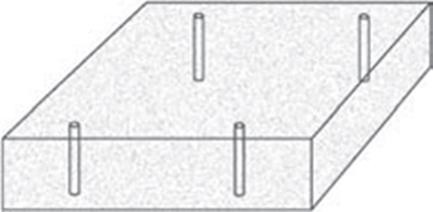

| PH-PLAIN | PH – PLAIN / perforated | VIC CUT – vacuum infusion |

|

|

|

Cuttings

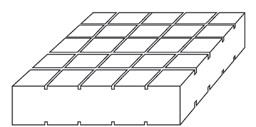

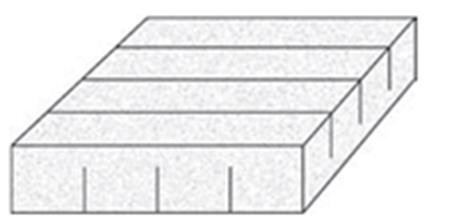

Typically composite structures are not plain, so the core materials should bend. This can be achieved by thermoforming or axial cuts. For example, the cuts improves air removal and spreading of the resin.

| SC – Single CUT | DC – Double CUT | CS – Contour Scrim |

|

|

|

Thermoforming

In thermoforming processes the sheets are bent into demanded shapes. Gurit’s Corecell and PVC are thermoformable core materials. Recommended processing temperatures for each product are provided in the table below.

Process:

1. Warming

2. Forming

3. Postforming

| Type | Product | Recommended thermoforming temperature (ºC) | Maximum thermoforming temperature (ºC) |

| Gurit® Corecell™ SAN (styrene acrylic nitrile) |

M | 110 | 120 |

| Gurit® PVC (polyvinyl chloride) |

PVC | 120 | 135 |

| PVC HT | 140 | 155 |

Hand lamination and infusion

All core materials are porous. The lower density and larger cell structure, the more resin is consumed. High resin consumption is also dependent on the manufacturing technique.

Prepreg/Sprint

Each core material type has a maximum temperature, where after their mechanical properties weaken.

| Type | Product | Normal processing temperature limit |

| Gurit® Corecell™ SAN (styrene acrylic nitrile) |

M | 120 ºC in 1 h |

| Gurit® PVC (polyvinyl chloride) |

PVC | not recommended for prepreg processes |

| PVC HT | 120 ºC in 1 h |

Core Brochure Structural core processing guide

Gurit® Corecell™

Corecell core material was developed to account for the inadequacies of PVC foam. SAN-based (styrene-acrylonitrile) foams are the forerunning core materials due to their natural toughness and ductility compared to e.g. PVC or other vinylester-based core materials. Corecell core materials are characterized by low creep, good impact resistance, good impact strength, heat resistant, and hydrostatic pressure resistant. Corecell is the optimal solution especially for demanding structured layer applications. Corecell’s is temperature resistant up to 120 °C; depending on the quality.

Corecell is suitable for use with polyester, vinylester, and epoxy; however, compatibility testing is recommended before applicably utilized.

Corecell is approved by Lloyds, DNV GL, and ABS.

CorecellTM M-Foam is a new generation of Corecell. It is suitable for all composite processing and prepreg applications due to it’s high heat resistance and can be used to replace PVC foams.

| Type | M60 | M80 | M100 | M130 | M200 |

|---|---|---|---|---|---|

| Density (kg/m3) | 65 | 85 | 107,5 | 140 | 200 |

| Color | green | blue/yellow | black | light brown | brown |

| Panel size (mm) | 1085×2606 | 1220×2240 | 1130×2275 | 1015×2045 | 1839×915 |

| Panel thickness (mm) | 5 – 38 | 5 – 38 | 5 – 32 | 5 – 32 | 5 – 30 |

Products ordered upon request. Panel inventory subject to change.

Gurit® PVC

NEW! Kevra offers its customers PVC foam manufactured in Europe. Nowadays, PVC core material is one of the basic raw ma terials used for manufacturing and mending of boats.

terials used for manufacturing and mending of boats.

Gurit® PVC is a closed cell, cross-linked PVC foam. It provides superior strength to

weight ratio for all composite applications.

Other key features of Gurit® PVC include outstanding chemical resistance, negligible

water absorption, and excellent thermal insulation capabilities. It is compatible with

most common resin systems including epoxy, polyester and vinylester.

The product is approved by DNV.

| Type / straight | PVC 40* | PVC 60 | PVC 80 | PVC 100* | Others* |

| Density (kg/m3) | 40 | 60 | 80 | 100 | |

| Color code | light blue | yellow | green | red | |

| Sheet size (mm) | 1330 x 2850 | 1150 x 2450 | 1020 x 2180 | 950 x 2050 | |

| Thickness (mm) | 5, 10, 15, 20 | 3 – 50 | 10, 15, 20 | 5, 10, 15, 20 |

| Type / contour scrim | PVC 40* | PVC 60 | PVC 80 | PVC 100* | Others* |

| Density (kg/m3) | 40 | 60 | 80 | 100 | |

| Color code | light blue | yellow | green | red | |

| Sheet size (mm) | 945 x 1130 | 1150 x 1220 | 1020 x 1080 | 950 x 1020 | |

| Thickness (mm) | 5, 10, 15, 20 | 3 – 50 | 10, 15, 20 | 5, 10, 15, 20 |

Also single PVC sheets are available from our stock, as well as sheets with other densities and different rutting and perforating (full boxes). Available upon request.