Vacuum injection

Vacuum infusion products are manufactured in open moulds. The opposite mould surface is replaced with vacuum bagging or a flexible complimentary mould. The primary method is to “suck” the resin into the reinforcement by means of a vacuum. The injection process can in some cases be accelerated by positive pressure, albeit this positive pressure must be less than the absolute value of the total vacuum pressure in order for the method to work. The flow of resin can be eased by conduit layers, different reinforcements, sandwich structures, and core material groovings. Different meshes/films are used for the conduit layers. Multiple layered reinforcements provide an improved conduit for resins.

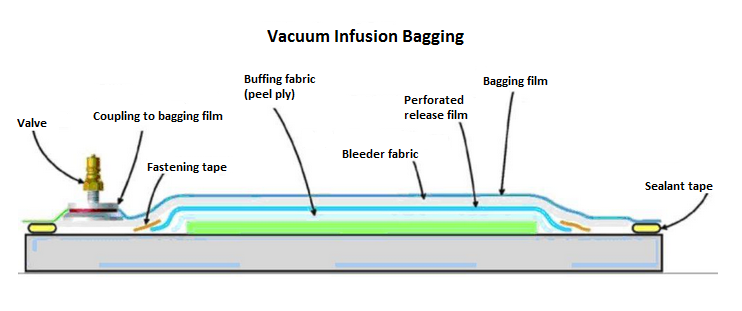

The principle vacuum injection method is shown in the picture below. If a smooth surface is required on both sides of the product or if large series production is needed, then the vacuum bagging can be replaced with a flexible mould usually comprised of resin channels and sealed edges. Flexible moulds are usually made of elastomers or reinforced plastics.

During injection, the matrix resin flows through the film and reinforcement layers. The areas of least resistance, which is where the resin naturally flows to first by means of the vacuum, are the thickest parts of the reinforcement system.. The advantages of this type of system are short flow-distances.

Compared to hand-lamination, vacuum injection systems are faster and more qualitatively consistent. The processes operate in a closed system, thus preventing volatile chemical agents to be spread throughout the workplace. Dry reinforcements are relatively easy to position onto the mould surface and the layers are bound together either mechanically or by an adhesive, e.g. spray-adhesive.