Carbon fibers

Carbon fiber in this context refers to a carbon content of 95-99 % by weight. It is characterized by it’s high modulus of elasticity and strength. Carbon fiber is well suited for plastic reinforcement applications.

Carbon fibers are manufactured from a suitable carbonized source material in a controlled process. There are numerous manufacturing methods; predominantly from PAN fibers (polyacrylonitrile fibers) because of it’s mechanical and physical properties. Carbon fibers are prepared into rovings/tows, in which filament-count depends on the manufacturer and application, ranging from a thousand to a few hundred thousand filaments. The most common untwisted roving filament-counts are 3 000 (3K), 6 000 (6K), 12 000 (12K), 24 000 (24K), and 48 000 (48K). Carbon fibers are suitable for thermoplastic and thermoset reinforcement. They are used primarily for ready-made manufactured products requiring light, strong, and stiff properties and/or for post-processing reinforcement applications.

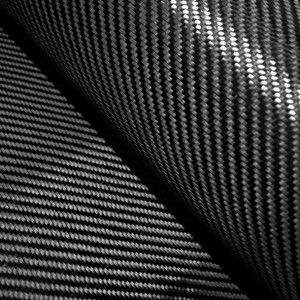

Carbon fiber weaves – Primetex

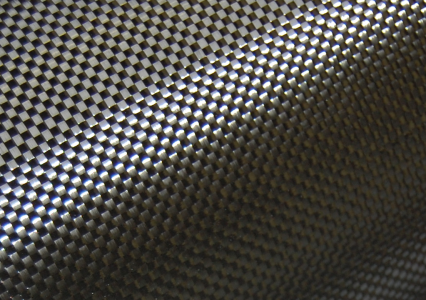

There are some differences in carbon fiber weaves even if their thicknesses are equivalent. A picture of Standard 200 g/m² is provided down to the left. A beautiful carbon fiber laminate can be achieved by laminating few layers. Next to the Standard type is Hexcel’s Primetex carbon fiber weave. Here the carbon fiber tows are flatted so that they lay next to each other. This type of weave functions as a good cover as well as it minimizes the gaps between the tows.

_  _______________________________________________________________

_______________________________________________________________

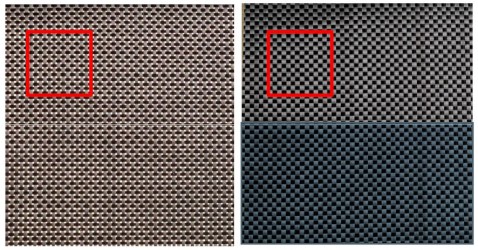

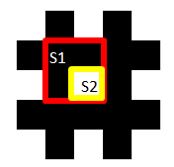

The gaps in a fabric can be described with an OF number (open factor). The value can be calculated according to the picture below:

OF number (%) = S2/(S1+S2)

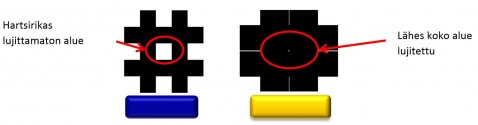

For example, Hexcel’s standard 193 g/m2 3K carbon fiber has an OF = 7,5 %, whereas the 193 g/m2 Primetex carbon fiber only has 0,5 %!! On the other hand, Hexcel’s standard 285 g/m2 6K fabric has an OF = 3 %, whereas Primetex with equivalent weight has OF = 0,5 %.

The advantages of Primetex can be described as following:

1. Less unreinforced areas in finished laminates. Resin without reinforcement is not so strong. The left picture below represents a resin-rich zone, whereas an almost 100 % reinforced zone is provided to the right.

2. Flattened fibers make it possible to use thicker carbon fiber tows. Thicker tows have lower price. For example, 100 g/m2 fabric is traditionally manufactured of 1 k carbon fibers. Hexcel’s Primetex-weave provides high homogeneous 100 g/m2 fabrics with 3 k fibers.

3. Specific dense carbon fiber laminate can be made of lighter carbon fiber fabric. Primetex 160 g/m2 carbon fiber fabric makes a good cover, possibly better cover than common 200 g/m2 fabric.

Primetex carbon fiber fabric is popular for cosmetic purposes, for example, in car tuning parts. Primetex fabrics provide enhanced mechanical properties in laminates, thanks to the lack of “resin pockets”.

Carbon fiber weaves

| Weight | Width | Weave | Tow | Warp Weft | Laminate thickness | Documentation | |

| Hexforce® 41090 | 90 g/m² | 1020 mm | plain | 1K | 50 50 | 0,09 mm | 41090 |

| Primetex® 43161 | 161 g/m² | 1250 mm | plain | 3K | 50 50 | 0,16 mm | 43161 |

| Primetex® 43162 | 162 g/m² | 1250 mm | twill 2/2 | 3K | 50 50 | 0,16 mm | 43162 |

| Primetex® 43200 | 200 g/m² | 1270 mm | twill 2/2 | 3K | 50 50 | 0,20 mm | 43200 |

| Hexforce® 43200 | 200 g/m² | 1270 mm | twill 2/2 | 3K | 50 50 | 0,20 mm | 43200. |

| Hexforce® 43285 | 285 g/m² | 1250 mm | twill 2/2 | 3K | 50 50 | 0,29 mm | |

| Hexforce® 48600 | 600 g/m² | 1300 mm | twilll 2/2 | 12K | 50 50 | 0,62 mm | 48600 |

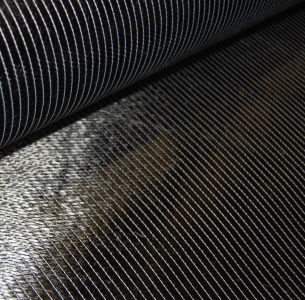

Carbon multi-axial

| Fiber direction | Weight | Width | Laminate thickness | |

| NLT00 HR1270 0160 | 0° / 90° | 160 g/m² | 1270 mm | 0,16 mm |

| NBB00 HR1270 0200 | +45° / -45° | 200 g/m² | 1270 mm | 0,20 mm |

| NBB00 HR1270 0400 | +45° / -45° | 400 g/m² | 1270 mm | 0,40 mm |

| NLT00 HR1270 0400 | 0° / 90° | 400 g/m² | 1270 mm | 0,40 mm |

Tapes

| Width | Tow | Weave | Laminate thickness | |

| Carbon tape 160 g/m2 | 170 mm | 3K | plain | 0,16 mm |

| Carbon tape 118/90 250 g/m2 | 90 mm | 3K | twill 2/2 | 0,25 mm |

| Carbon tape 320 g/m2 | 37 mm | 12K | UD | 0,35 mm |

| Carbon tape 340 g/m2 | 50 ja 100 mm | 12K | UD | 0,35 mm |

| Carbon tape XCT411 g/m2 | 140 mm | 12K | biaxial | 0,42 mm |