Vacuum infusion supplies are used in manufacturing of advanced composite structures. Applications are vacuum bagging of hand laminated products, vacuum infusion and prepreg manufacturing. Vacuum bagging provides lightweight, homogeneous and stronger pieces. In the process, a vacuum pump and suitable valves are required, as well as vacuum gauges, couplings (also inlet couplings), hoses and a vessel for excessive resin. Also these supplies are available from Kevra.

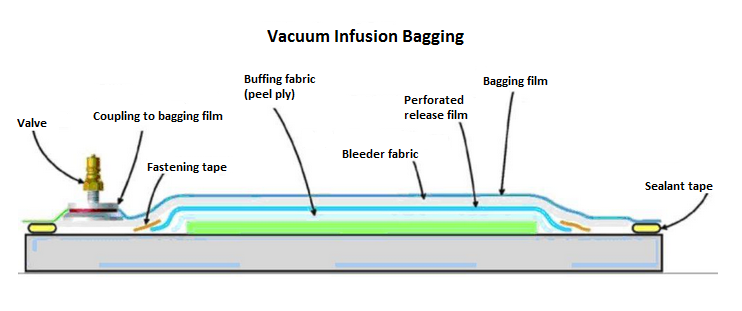

Bleeder fabrics conform to complex shapes without losing their functional distribution properties while uniformly spread under the bagging film. The bleeder fabric’s function is to allow for the flow of resin and excess air throughout the shaped/deformed layer as the vacuum pressure is applied. In most cases it is possible to use the same fabric for suction and air removal.

Flow mats are used in vacuum infusion to improve the resin flow throughout the dry fibers.

The release film must have good strength, toughness, and elasticity. They must be able to form to complex shapes without tearing. The type of film selected is dependent on the matrix material used, the product’s shape, and the temperature. The release film’s functions are to release the laminate and to prevent the laminate from sticking to the bleeder fabric.

Peel plies are used on the moulded body’s surface for cosmetic reasons, usually pertaining to gluing, painting, or other surface treatments after the curing process. It’s use stems importantly from improving surface adhesion properties. Peel plies may be used on either directly on the mould surface or the products outer surface.

Flash tape is intended for attaching films. Flash tape usage as fastening tape is recommended when the temperature rises above 80°C.

Bagging films are flexible and typically 0,050 – 0,075 mm thick. They are made from either polyamide or combinations of plastics, making the film air-tight. They don’t become holey as easy as e.g. building plastics, thus they perform more reliable than common plastic films.

Sealant tape is used to seal the bagging film, so that the system is air-tight. The tape is approx. 12 mm wide and 3 mm thick, it adheres well as well as it conforms to advanced shapes. Sealant tapes are available with varying degrees of thermal resistance, which makes them suitable for different manufacturing methods.